Chemical Resistance

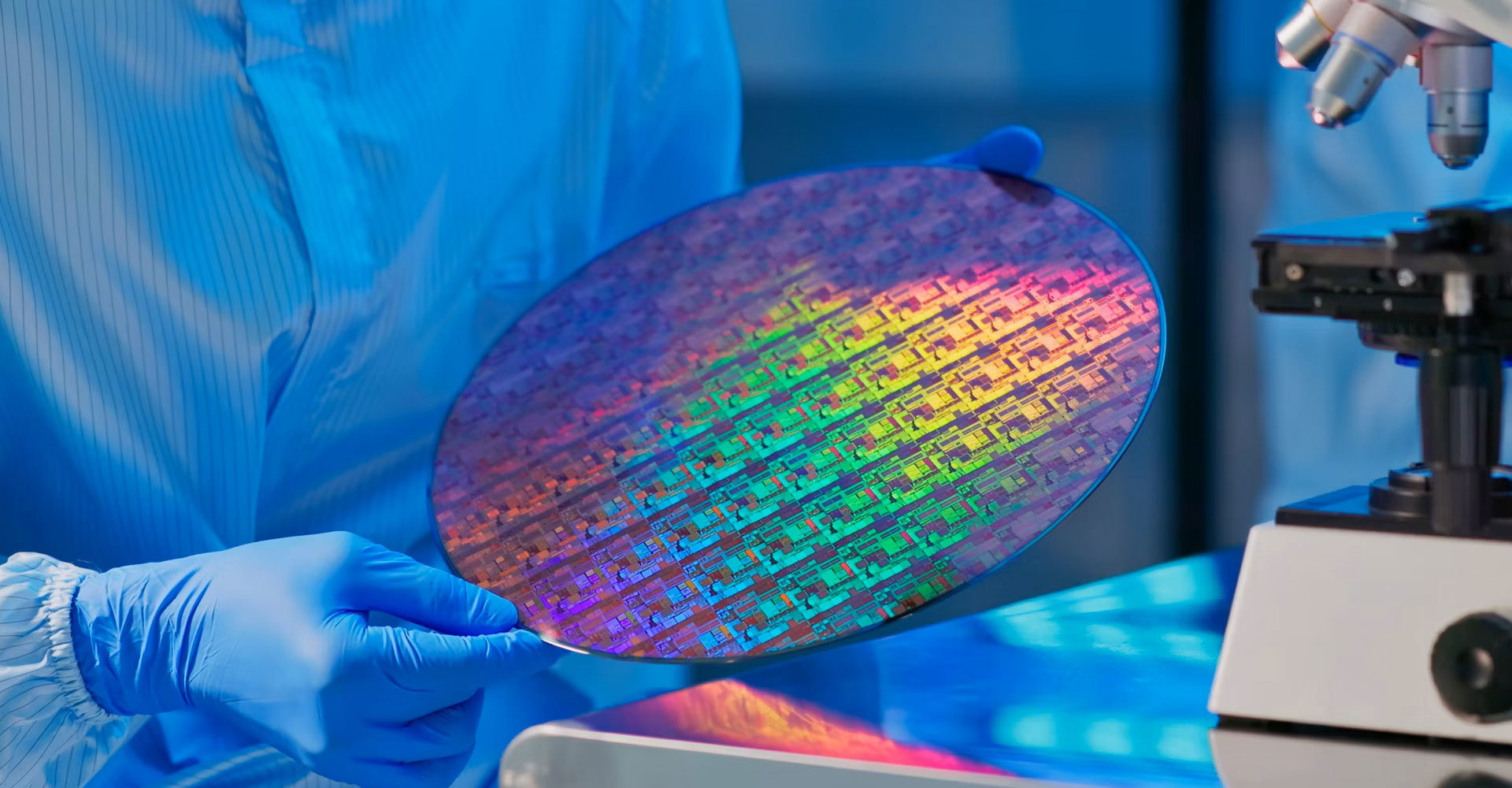

Perfluorinated rubber (FFKM) components resist corrosion from more than 1,600 different chemicals, solvents and plasmas. Our products demonstrate superior performance in corrosive process environments. Whether faced with acidic, alkaline, amine, plasma or ultra-pure deionized water, manufacturers can effectively improve the sealing effect by selecting the most suitable parts for the specific application. We offer components in a wide range of compound formulations designed to optimize performance and ensure optimal performance across a wide range of chemicals and temperatures.

Minimal Swell

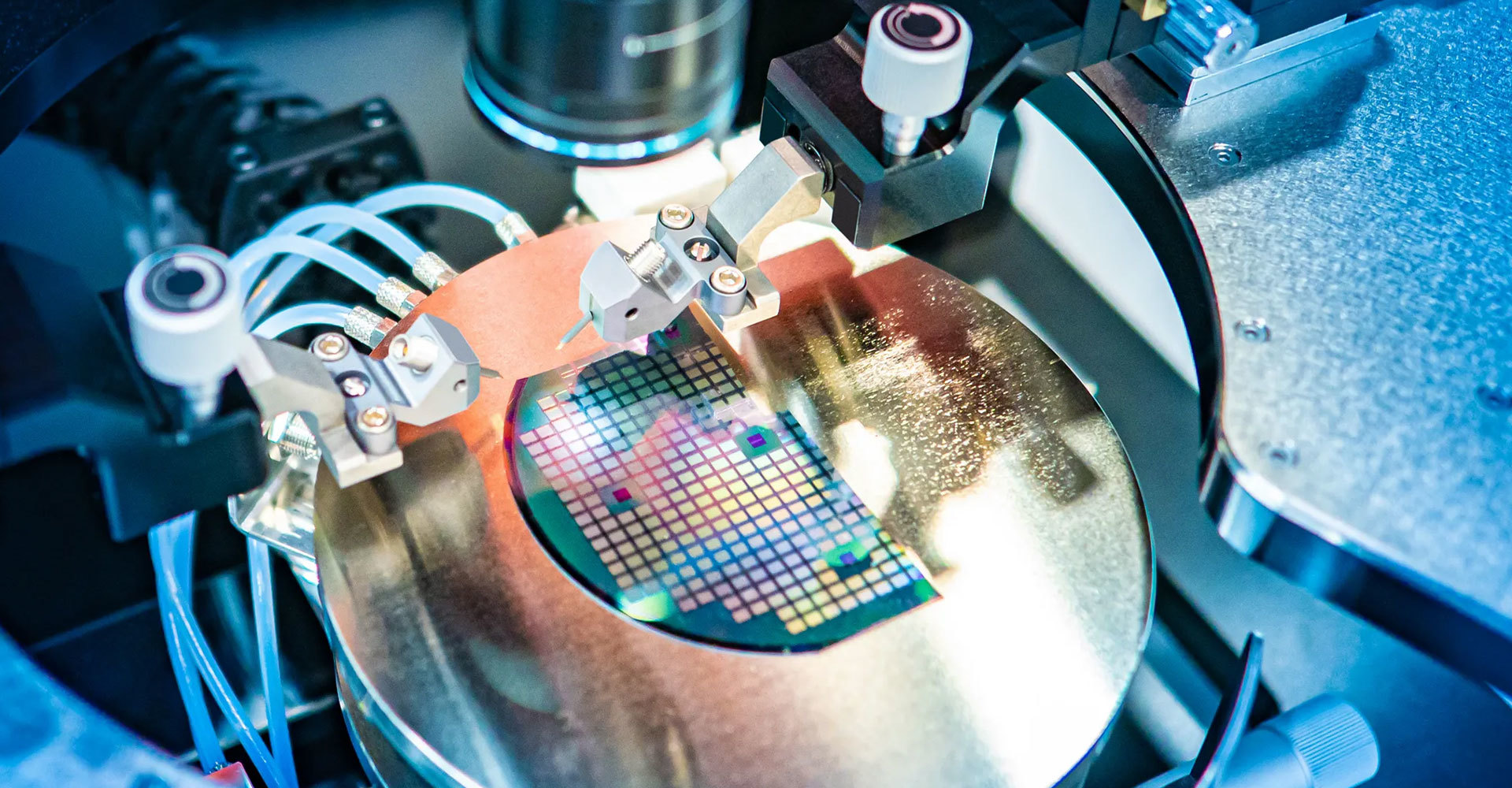

Chemically induced swelling can cause O-rings and sealing components made of other elastomers to extrude out of seal grooves, resulting in seal failures. Materials such as FFKM (fluorinated elastomers) have excellent chemical stability and high temperature resistance, and generally have a low coefficient of expansion. This allows FFKM to maintain its size and elasticity in high temperature and pressure environments, providing reliable sealing performance in demanding sealing applications. They have proven to be a cost-effective solution in situations where seals with maximum resistance to harsh chemical environments and high temperatures are required.

FFKM Parts Chemical Resistance

Perfluorinated rubber (FFKM) components resist corrosion from more than 1,600 different chemicals, solvents and plasmas. Our products demonstrate superior performance in corrosive process environments. Whether faced with acidic, alkaline, amine, plasma or ultra-pure deionized water, manufacturers can effectively improve the sealing effect by selecting the most suitable parts for the specific application. We offer components in a wide range of compound formulations designed to optimize performance and ensure optimal performance across a wide range of chemicals and temperatures.

Minimal Swell

Chemically induced swelling can cause O-rings and sealing components made of other elastomers to extrude out of seal grooves, resulting in seal failures. Materials such as FFKM (fluorinated elastomers) have excellent chemical stability and high temperature resistance, and generally have a low coefficient of expansion. This allows FFKM to maintain its size and elasticity in high temperature and pressure environments, providing reliable sealing performance in demanding sealing applications. They have proven to be a cost-effective solution in situations where seals with maximum resistance to harsh chemical environments and high temperatures are required.

Related Products

More Solutions