Minimize wafer contamination

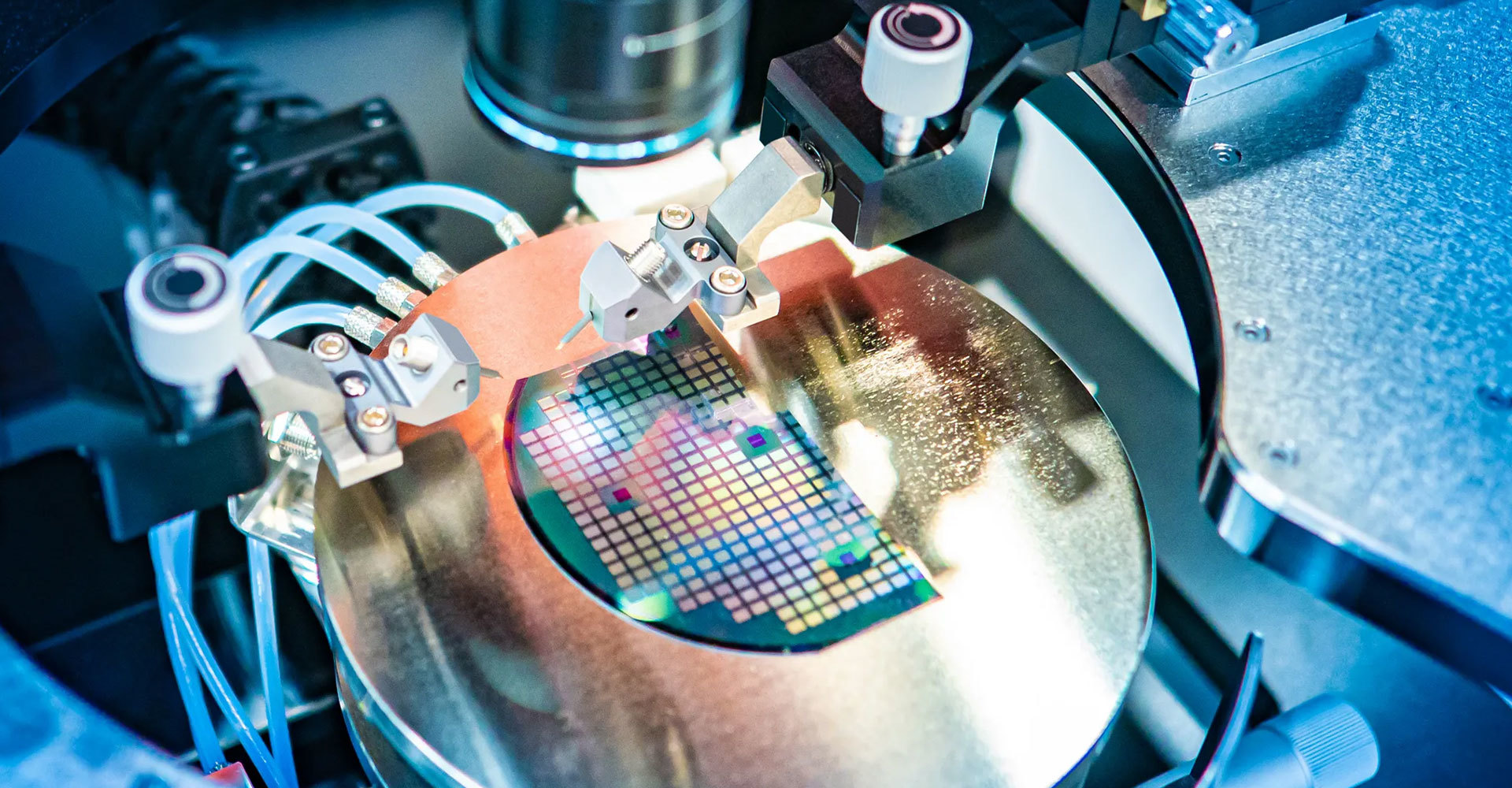

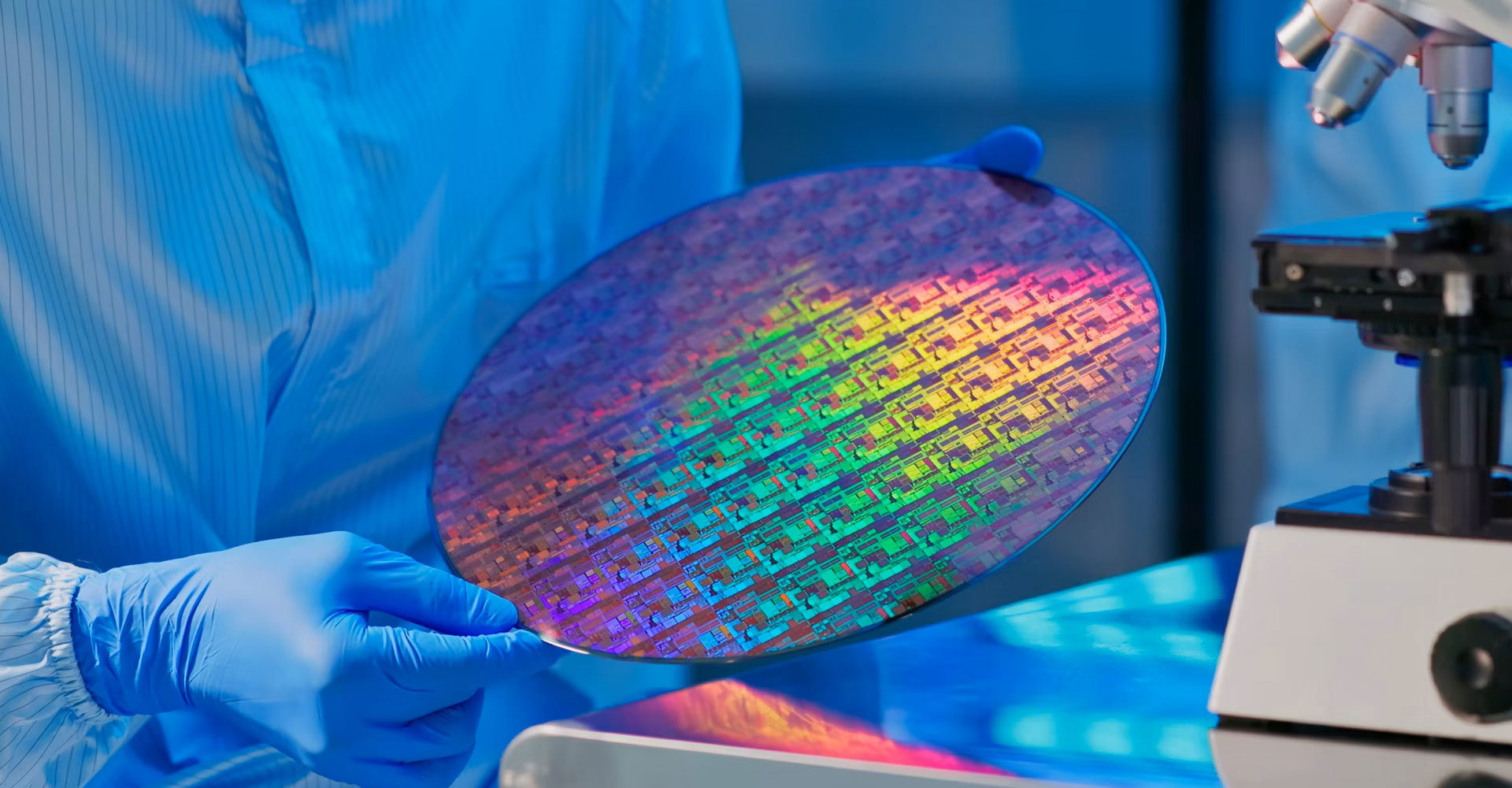

Perfluorinated rubber (FFKM) is used as a seal on wafer processing equipment due to its superior resistance to chemicals, including reactive plasma and extreme temperatures up to 330°C. FFKM seals, through their excellent chemical resistance, low gas yield, low particle formation, high temperature stability and chemical reaction avoidance characteristics, can effectively reduce wafer pollution during the production process, ensure a clean environment in the semiconductor manufacturing process and guarantee the quality of the final product.

Weight Loss / Particle Generation

As a powerful etching, chemical vapor deposition (CVD) and stripping tool in semiconductor manufacturing, plasma is extremely consumable of materials. FFKM seals are widely used in these processes because of their excellent corrosion resistance. However, prolonged exposure to plasma can lead to seal surface degradation, which in turn increases the risk of particle contamination, affecting wafer yield and process reliability. Therefore, the ideal seal needs to maintain its sealing function while resisting surface degradation. FFKM seals are designed to resist chemical attack, extend seal life, reduce weight loss and particle generation, thereby increasing wafer yield, process reliability, and reducing equipment maintenance frequency.

FFKM Seals Help Minimize Wafer Process Contamination

Perfluorinated rubber (FFKM) is used as a seal on wafer processing equipment due to its superior resistance to chemicals, including reactive plasma and extreme temperatures up to 330°C. FFKM seals, through their excellent chemical resistance, low gas yield, low particle formation, high temperature stability and chemical reaction avoidance characteristics, can effectively reduce wafer pollution during the production process, ensure a clean environment in the semiconductor manufacturing process and guarantee the quality of the final product.

Weight Loss / Particle Generation

As a powerful etching, chemical vapor deposition (CVD) and stripping tool in semiconductor manufacturing, plasma is extremely consumable of materials. FFKM seals are widely used in these processes because of their excellent corrosion resistance. However, prolonged exposure to plasma can lead to seal surface degradation, which in turn increases the risk of particle contamination, affecting wafer yield and process reliability. Therefore, the ideal seal needs to maintain its sealing function while resisting surface degradation. FFKM seals are designed to resist chemical attack, extend seal life, reduce weight loss and particle generation, thereby increasing wafer yield, process reliability, and reducing equipment maintenance frequency.

Related Products

More Solutions